(Newswire.net — December 2, 2022) —

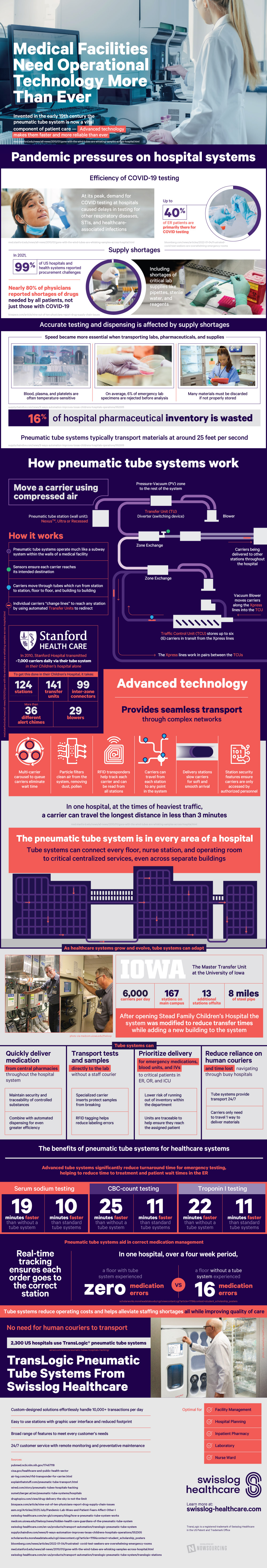

The COVID-19 pandemic h severely impacted the world in many ways. However, none has been hit more severely than the medical industry. During the peak of the pandemic, there was a lot of pressure put on hospital systems. Because there was so much demand for COVID testing in hospitals, there were delays in testing for other respiratory diseases such as STIs and other healthcare-associated infections. On average, up to 40% of ER patients were there primarily for COVID testing.

While we are in the recovery stage of the pandemic, supply shortages are still a pressing issue that hospitals are facing right now. In 2021, 99% of US hospitals and health systems reported having procurement challenges. Moreover, nearly 80% of physicians reported shortages of drugs needed by all patients, not just those with COVID-19. These shortages extend to lab supplies like pipettes, sterile water, and reagents.

Supply shortages affect the testing and dispensing of materials as well. Speed became essential when transporting labs, pharmaceuticals, and supplies. Some examples are blood, plasma, and platelets are often temperature-sensitive. Likewise, shortages create difficulties in material storage, meaning they are often discarded. This has led to 16% waste in pharmaceutical inventory. Inadvertently the pandemic has opened up an issue that existed way before it, and there needs to be a way to efficiently transport materials while still maintaining the quality of care for patients. Medical facilities need operational technology more than ever. A proven method of delivery is the pneumatic tube system.

Invented in the early 19th century, the pneumatic tube system is now becoming a vital component in patient care. Applying the latest technology to this system makes them even faster and more reliable than ever. Unlike traditional couriers, the pneumatic tube system typically transports materials at around 25 feet per second. Even on days with heavy traffic, material carriers can travel the longest distance in less than 3 minutes. How it works is that materials are transported via a carrier and the vehicle of movement is wind using a blower. Sensors ensure each carrier reaches its intended destination. Carriers move through tubes from station to station, floor to floor, and building to building. Individual carriers “change lines” to reach any station by using automated transfer units to redirect and control the flow of traffic.

When advanced technology is implemented it takes the pneumatic tube system to the next level. There is a multicarrier carousel to queue carriers to eliminate waste time. Particle filters are installed to filter clean air from the system removing dust and pollen. RFID transponders help track each carrier and can be read from all stations. Then, there are delivery stations to slow carriers for a soft and smooth arrival so delicate materials can remain intact. To ensure security in every transport, there are station security features put in so that only authorized personnel can access the carriers. Pneumatic tube systems are also versatile because they can connect to every area of the hospital. Tube systems can connect to every floor, nurse station, and operating room. As healthcare systems grow and evolve, tube systems can adapt and advance.

Source: Swisslog Healthcare